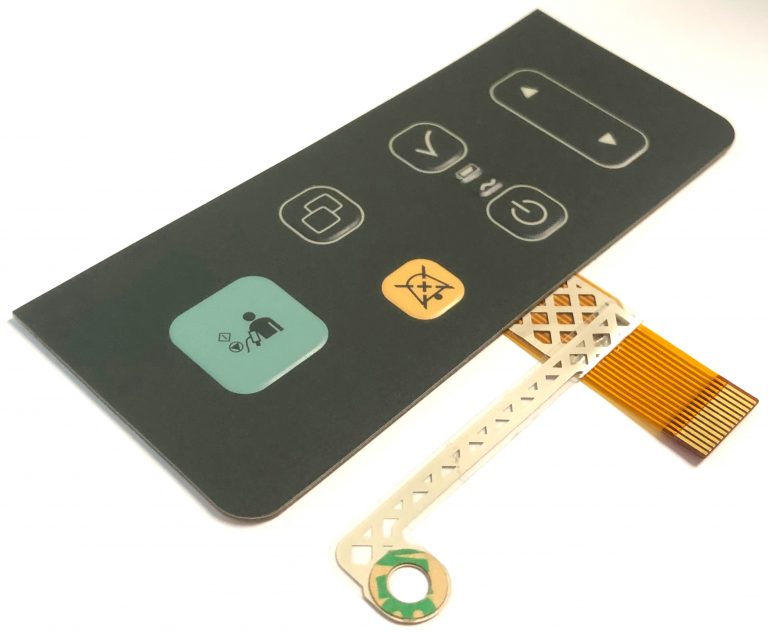

The services offered by a specialized membrane switch manufacturer go beyond standard-level production.

The services offered by a specialized membrane switch manufacturer go beyond standard-level production.

Blog Article

Usual Uses of Membrane Layer Switch in Various Industries and Applications

Membrane layer switches play an essential function in many sectors, improving functionality and user experience. Whether you're navigating a medical tool or regulating a home appliance, these functional switches are designed to meet specific requirements. Their durability sought after settings makes them a popular option throughout sectors. Curious concerning exactly how these switches are transforming different applications? Allow's discover their significant contributions in various fields.

Membrane Layer Switches in Customer Electronics

Membrane layer buttons play a necessary duty in the performance of consumer electronics, enhancing customer experience with their sleek design and responsive interface. You'll find them in devices like smartphones, tablet computers, and home appliances, where they offer a seamless means to interact with innovation. These buttons are light-weight, sturdy, and customizable, making them ideal for different applications.

When you push a membrane layer button, it produces a trustworthy feedback that aids you navigate your device easily. Their low-profile design suggests they can match small spaces, maintaining the aesthetic appeal of your gadgets. And also, they're immune to dirt and moisture, making certain lasting efficiency.

As you check out the world of customer electronic devices, you'll see how membrane layer changes add to user-friendly controls and boost your total experience (membrane switch manufacturer). By incorporating innovation with feature, these buttons help you attach with your devices in a more meaningful method

Applications in Clinical Instruments

When it pertains to clinical gadgets, interface style is vital for guaranteeing simplicity of use. Membrane changes offer resilience and are easy to clean, making them optimal for preserving health in medical care settings. You'll discover that these functions improve both performance and safety in medical applications.

Interface Layout

In the domain name of clinical tools, individual interface layout plays an important role in ensuring safety and security and effectiveness, as it directly impacts just how healthcare specialists and individuals engage with the devices. You need interfaces that are intuitive and simple to browse, reducing the chances of mistakes throughout important scenarios. Clear labeling, logical layouts, and responsive comments are crucial elements that improve use. With a properly designed interface, you can improve procedures, allowing quicker accessibility to critical functions. Furthermore, incorporating individual testing assists identify discomfort points, allowing you to improve the style even more. Remember, efficient user interface style not just improves customer experience but additionally adds to much better individual end results by cultivating precise and prompt interactions with medical tools.

Sturdiness and Hygiene

Toughness and hygiene are critical consider the design of medical devices, as they ensure that tools can endure strenuous usage while keeping cleanliness. Membrane layer changes play a vital function below, using a robust and easy-to-clean interface. Their secured building avoids dust, liquids, and pollutants from getting in, making them perfect for atmospheres like healthcare facilities and clinics. You'll discover that these switches can endure rough cleaning representatives without deteriorating, guaranteeing lasting efficiency. In addition, their smooth surface lessens microbial growth, advertising a sanitary atmosphere for both people and medical care employees. By incorporating membrane buttons in clinical devices, you're guaranteeing a trustworthy and sterile individual experience, which is crucial for patient safety and security and functional efficiency in medical care settings.

Automotive Controls and Instrumentation

As vehicle innovation evolves, membrane layer switches have actually ended up being essential for controls and instrumentation in modern-day cars. These buttons provide a streamlined style, enabling smooth integration into control panels and control panels. You'll locate them in whatever from infomercial systems to climate controls, boosting user experience with their user-friendly interfaces.

Membrane buttons offer responsive feedback, which aids you navigate complicated features without diversion. They're also lightweight and immune to moisture, making them suitable for automotive atmospheres. With personalized graphics, you can customize the format to fit specific requirements while making certain toughness versus wear and tear.

In addition, these buttons can be developed with backlighting alternatives, enabling exposure in low-light problems. This capability improves safety and security and convenience as you drive. Generally, membrane layer switches over not just meet the aesthetic demands of contemporary cars yet also contribute considerably to their functional performance and customer satisfaction.

Industrial Equipment and Tools

Membrane layer buttons play an important role in modern-day commercial machinery and equipment, official site enhancing both performance and use (membrane switch manufacturer). You'll discover them in control panels for manufacturing makers, where they supply a trustworthy user interface for drivers. Their portable layout fits flawlessly into tight spaces, enabling for reliable formats

These switches are resilient, withstanding severe problems such as dirt, moisture, and temperature fluctuations. That indicates they can hold up against the roughness of factory environments while maintaining efficiency. You can conveniently personalize membrane switches to suit details equipment demands, whether it's for labeling or tactile feedback.

With easy installment and maintenance, they save you time and sources. Plus, their visual appeal can contribute to an expert search in your procedures. Overall, incorporating membrane layer switches into your industrial machinery enhances customer experience and enhances overall efficiency, making them a wise choice for any operation aiming to optimize its equipment.

Home Devices and Control Panels

When it comes to home appliances, membrane layer buttons use an intuitive interface style that makes operating your devices a breeze. You'll appreciate their toughness and durability, guaranteeing your controls stand up to everyday use without losing performance. Let's discover how these functions improve your everyday experience.

Individual Interface Style

Individual interface layout in home appliances and control panels plays a vital function in enhancing user experience. Membrane changes permit for sleek, modern-day designs that can incorporate perfectly right into your appliances. By making use of tactile responses and aesthetically appealing graphics, these switches assist you through functions without confusion.

Resilience and Longevity

Pc Gaming and Entertainment Systems

Membrane layer switches play a vital role in pc gaming and amusement systems, boosting individual communication with streamlined and receptive controls. You'll locate them in whatever from gallery machines to gaming consoles and handheld devices. Their level style enables for simple assimilation right into numerous surfaces, providing tools a modern and structured appearance.

These buttons make it possible for fast feedbacks, making your pc gaming experience extra interesting and delightful. With personalized graphics and formats, suppliers can produce distinct interfaces that show the game's style, drawing players in. And also, membrane buttons are durable and immune to use, guaranteeing they can hold up against the roughness of intense gaming sessions.

Additionally, their ability to provide responsive responses suggests you can really feel the feedback as you communicate with the video game. Overall, membrane buttons are crucial parts that raise the capability and aesthetic charm of gaming and home entertainment systems, making your play try this out even a lot more immersive.

Aerospace and Defense Applications

In the high-stakes globe of aerospace and protection, reliability and accuracy are vital. Membrane layer buttons play a necessary role in ensuring that your devices runs perfectly in requiring atmospheres. You'll find these switches in cabins, military vehicles, and interaction systems, where they provide user-friendly control over crucial features.

Their flexible style permits you to incorporate them seamlessly into different surface areas, maximizing space and functionality. Furthermore, membrane layer switches are resistant to severe problems, including extreme temperatures and wetness, making them excellent for aerospace applications.

You'll appreciate the responsive feedback these switches use, enhancing your individual experience by guaranteeing you recognize when a command has actually been carried out. With their longevity and customizability, membrane layer changes empower you to maintain high functional requirements in objectives where every choice counts. Accepting this modern technology can significantly improve security and effectiveness in your aerospace and defense projects.

Frequently Asked Inquiries

Exactly How Do Membrane Changes Contrast to Typical Mechanical Switches?

Membrane changes use a smooth, inconspicuous layout and are commonly a lot more durable than conventional mechanical switches. You'll find they're simpler to clean, quieter, and can incorporate personalized graphics, boosting user experience substantially.

What Products Are Generally Made Use Of in Membrane Layer Switch Construction?

Can Membrane Switches Over Be Custom-made for Details Applications?

Yes, you can tailor membrane buttons for specific applications. By picking products, shades, and formats, you'll create a layout that fulfills your demands. This flexibility makes them suitable for numerous gadgets and interfaces.

What Is the Common Lifespan of a Membrane Switch?

The typical life expectancy of a membrane layer switch varies from 5 to 10 million presses, relying on material quality and use. You'll wish to examine variables like ecological conditions and application frequency for precise durability price quotes.

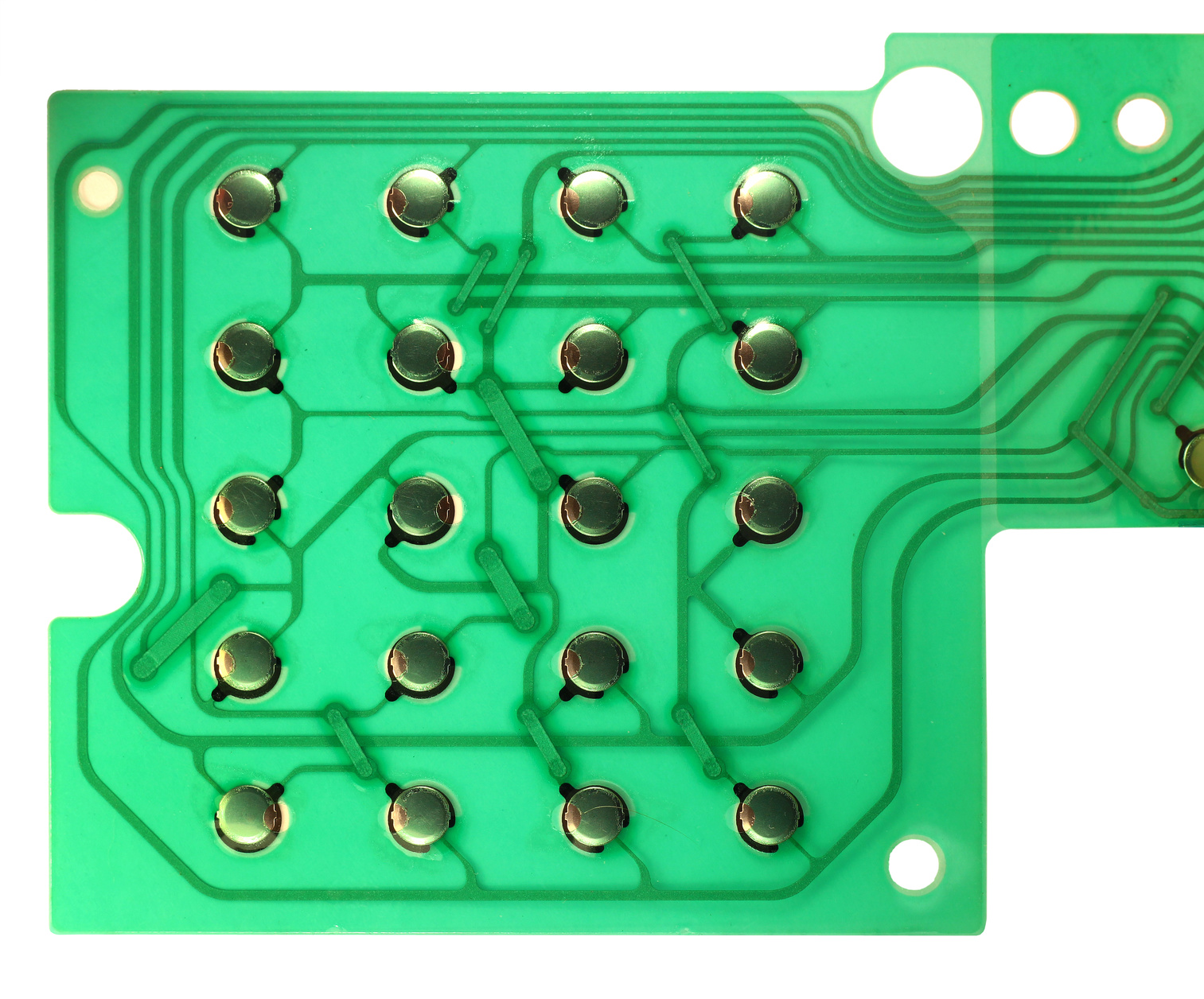

Exactly How Are Membrane Switches Over Manufactured and Evaluated for High Quality?

To manufacture membrane layer buttons, you begin with substrate layering, applying sticky and printing circuits. After setting up, you evaluate for capability, longevity, and environmental resistance, guaranteeing they fulfill top quality standards prior to completing manufacturing.

Final thought

In recap, membrane layer buttons play a crucial role in boosting individual experience across various sectors. Whether you're maneuvering a mobile phone or operating clinical devices, their personalized and long lasting layout guarantees reliability and effectiveness. As you discover different applications, you'll appreciate the responsive comments and dampness resistance that make these switches ideal for demanding atmospheres. Welcoming membrane layer switches can considerably improve functionality and satisfaction in consumer electronics, vehicle controls, commercial machinery, and past.

Report this page